2017 - 2020

Formula SAE

Scroll ↓

What is Formula SAE?

“The Formula SAE competitions challenge teams of university undergraduate and graduate students to conceive, design, fabricate, develop and compete with small, formula style vehicles. The competition is an engineering education competition that requires performance demonstration of vehicles in a series of events, both off track and on track against the clock. Each competition gives teams the chance to demonstrate their creativity and engineering skills in comparison to teams from other universities around the world.”

Nontechnical Skills

Leadership

During my time with the team, I have lead several workshops and presentations on top of aiding in project management. Pictured here is an overview presentation I gave to the team on using a 3D scanner to reverse engineer components. This presentation was a precursor to the workshop where I guided junior members through practice scanning other engine components.

I am most proud of the internal design competition that I lead for the team. With classes online and the team spread apart, I was thinking of creative ways to keep current and prospective members engaged. The competition revolved around the development of a push bar for rolling the car between events at the physical competition. It was a simple enough part that people of all skill levels could enter and come up with creative solutions. Following the success of the competition with great learning and team bonding outcomes, I hope the framework I set up will be used for many more internal design competitions to come.

Teamwork

One of the struggles our team faced was the retention of new members. As volunteers, there is no obligation to stay with the team and members are self-motivated. It’s difficult to come up with meaningful projects to engage new members when both you and them are unsure of their commitment. This results in the dilemma of risking a critical project left unfinished or handing out mundane tasks. So the question is: how do you motivate volunteers without concrete incentives?

After much contemplation and observation of the top teams at competitions, I came to the conclusion that the answer lies with members’ sense of belonging. Aligning with Maslow’s Hierarchy of Needs, fostering comradery and a sense of belonging is a critical part of any team - as humans we need our psychological needs met before we can derive motivation for and satisfaction from our accomplishments.

The very first thing I urged the team to implement was a gold star chart. Members could earn gold stars by volunteering at events with the team and a certain amount was required to be eligible to attend competition. However, the gold stars were never the point. The point was that a new member could come into the office and see their name up on the wall with the rest of the team: concrete evidence showing they belonged. The team saw an approximate 30% growth in sustained membership the season this strategy was implemented.

Communication & Documentation

One of the biggest problems that plague most Formula SAE teams is knowledge transfer and retention. In 2010, the University of Alberta team was ranked fourth in the world, but by 2014, they had to withdraw from competition - all the hard work put into those cars was lost with those who graduated. Seeing how handoff notes were often lost or shoved into a filing cabinet, I set up an internal wiki for the team. Going forward, all team knowledge is organized and consolidated here. My hope is for future team members to be able to search the wiki and build upon the lessons learned from alumni.

Technical Skills

Penultimate Performance

The most advanced part I designed for Formula SAE was a small tab. Though small, the upper ball joint tab must endure the very high forces transmitted from the wheel to the suspension. For a racecar, however, a big chunk of steel will not do. In terms of performance, the mass of the car should be minimized, especially for the unsprung mass of the wheel assemblies.

Because of the high-strength and minimum mass constraints, this tab was an excellent candidate for topology optimization. The optimized tab was then sent to be 3D printed from titanium. This approach and redesign of the upright sub-assembly reduced mass by 20% compared to its predecessor.

This part was also an excellent candidate for an international design competition hosted by Stratasys and GrabCAD. I submitted the design with an accompanying report. I took first place in the competition, winning a US$2500 scholarship.

Testing & Validation

Simulation suites nowadays have become quite refined, but there are still many assumptions and compromises engineers make to numerically model a system. Performing physical tests to validate the assumptions made is critical to the design process.

Unfortunately, with the delays caused by COVID-19 I haven’t been able to implement my test procedures planned for my most recent designs. However, going into the previous design cycle I was able to take data logs from the car to confirm some of the vehicle’s dynamic properties. Most interestingly, I was able to use the failure of the wheel’s upright to qualitatively validate boundary conditions set up for a stress analysis.

Manufacturing

The majority of my fabrication work with the Formula team involved CNC machining of molds for carbon fiber composite parts. The team was generously donated their CNC router with no clear origin or documentation. Before the team entered the fabrication phase, I looked to improve the accuracy of the machine.

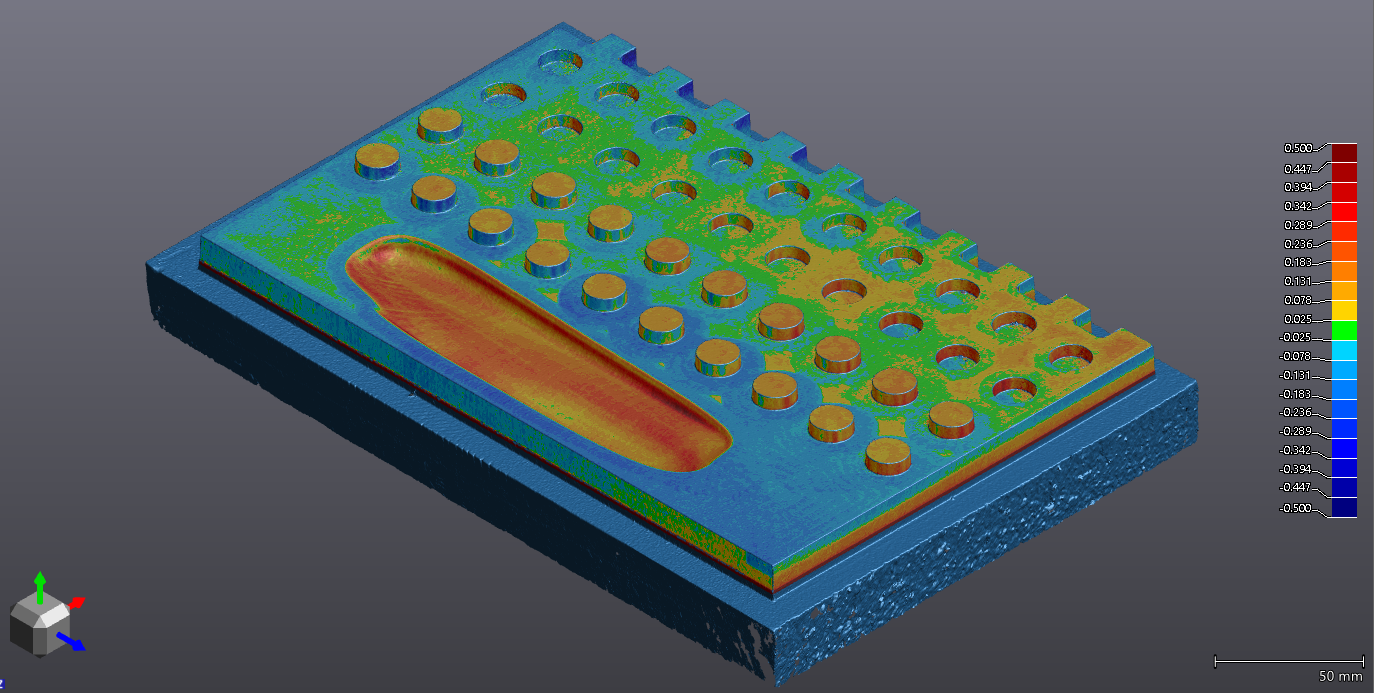

Using a Creaform MetraSCAN 3D scanner, I was able to generate the plot shown here to get a better visualization of the machine’s performance. I then also conducted statistical process control (SPC) to obtain some baseline performance metrics. Machine performance was checked for different machining strategies and after any modifications made, with a notable improvement after designing and implementing a new Z-axis assembly.